Best Things To 3D Print? Dude, it’s way more than just geeky gadgets! From practical everyday objects that totally upgrade your life to mind-blowing artistic creations and super-cool hobby projects, 3D printing opens up a whole new world of possibilities. Think custom phone cases, intricate jewelry, even miniature figurines for your next epic tabletop campaign. We’re diving deep into the best things you can create, the tech behind it, and how to avoid those pesky printing fails.

This guide breaks down everything you need to know, whether you’re a total newbie or a seasoned maker. We’ll cover different 3D printing technologies, materials, design tips, and troubleshooting advice – all in a totally relatable, easy-to-understand way. Get ready to unleash your inner maker and create something awesome!

Practical Applications of 3D Printing

3D printing offers a wealth of practical applications, transforming how we create and utilize everyday objects. Its ability to produce customized items on demand, coupled with the versatility of materials, makes it a powerful tool for both personal use and small-scale manufacturing. Let’s explore some key examples.

Everyday Objects Best Suited for 3D Printing

The suitability of an object for 3D printing hinges on factors like design complexity, material properties, and the desired production volume. Below is a table highlighting examples, considering these factors.

| Object | Material | Advantages | Disadvantages |

|---|---|---|---|

| Phone Stand | PLA | Lightweight, customizable design, easy to print | Relatively brittle, may not withstand heavy use |

| Small Organizer | PETG | Durable, impact-resistant, good layer adhesion | More challenging to print than PLA, requires higher temperatures |

| Customizable Tool Handles | ABS | Strong, heat-resistant, good for functional tools | Can warp easily during printing, requires enclosed printing environment |

| Replacement Parts | Nylon | High strength-to-weight ratio, flexible, good for intricate parts | More expensive than other filaments, requires specialized printers |

Designing a Functional 3D-Printed Tool: A Phone Stand Example

Designing a functional 3D-printed phone stand involves several steps. First, sketch the design, considering ergonomics and phone size. Then, utilize CAD software (like Tinkercad or Fusion 360) to create a 3D model, ensuring structural integrity and printability. Adjust parameters like wall thickness and infill density to optimize strength and reduce material usage. Finally, export the design in an STL format for slicing and printing.

3D-Printed Solutions to Common Household Problems

Source: ytimg.com

3D printing provides creative solutions to everyday problems. For instance, a broken appliance part can be easily replaced with a custom-printed one. Damaged furniture pieces can be repaired or customized with 3D-printed components. Specialized tools, such as custom-sized wrenches or adapters, can be created to address specific needs.

Creative and Artistic 3D Printing Projects: Best Things To 3D Print

Beyond practical applications, 3D printing opens a world of creative possibilities, allowing for intricate designs and personalized artistic expressions. Let’s delve into some exciting projects.

Designing Miniature Figurines for Tabletop Gaming

Creating miniature figurines involves sculpting a 3D model using digital sculpting software like Blender or ZBrush. Attention to detail is crucial, ensuring accurate proportions and realistic features. Materials like resin (SLA/DLP printing) are ideal for achieving high detail and smooth surfaces. Post-processing, including painting and basing, enhances the final product’s visual appeal.

Explore the different advantages of Redeem Roblox Code that can change the way you view this issue.

Creating Intricate 3D-Printed Jewelry

3D-printed jewelry allows for complex and unique designs not easily achievable with traditional methods. Materials like resin (SLA/DLP) are favored for their ability to produce fine details. Design software allows for intricate patterns and textures. Post-processing often involves polishing and plating to enhance the finish and durability.

Step-by-Step Guide for 3D Printing a Custom Phone Case

First, scan your phone to get accurate dimensions using a 3D scanner or manually measure it. Design the case in CAD software, considering button placements and overall fit. Experiment with different designs and textures. Then, export the STL file, slice it using appropriate software, and print using a suitable filament (like TPU for flexibility).

3D Printing for Hobbyists and Makers

3D printing has become increasingly accessible to hobbyists and makers, offering a fantastic avenue for creativity and innovation. Understanding the different technologies and troubleshooting common issues is key to a successful hobby.

Comparing 3D Printing Technologies for Hobbyists, Best Things To 3D Print

Fused Deposition Modeling (FDM) is the most common and affordable technology, using a heated nozzle to extrude filament. Stereolithography (SLA) and Selective Laser Sintering (SLS) offer higher resolution and detail but are more expensive. FDM is best for prototyping and functional parts, while SLA and SLS are better suited for detailed models and intricate designs. Material compatibility varies across technologies.

Essential Tools and Materials for 3D Printing

A successful 3D printing hobby requires several essential tools and materials. This includes a 3D printer, filament (PLA is a good starting point), a slicer software (Cura or PrusaSlicer), a pair of pliers, screwdrivers, and potentially a small set of cleaning tools for maintenance.

Troubleshooting Common 3D Printing Issues

Warpage, stringing, and layer adhesion problems are common issues. Warping can be mitigated by using a heated bed and enclosure. Stringing can be reduced by adjusting retraction settings. Layer adhesion problems can be addressed by cleaning the print bed, ensuring proper bed leveling, and using appropriate adhesion aids.

Advanced 3D Printing Techniques and Materials

Exploring advanced techniques and materials expands the creative and functional possibilities of 3D printing. Let’s examine some key aspects.

Properties of Various 3D Printing Filaments

- PLA (Polylactic Acid): Biodegradable, easy to print, good for prototypes and everyday objects.

- ABS (Acrylonitrile Butadiene Styrene): Strong, heat-resistant, suitable for functional parts.

- PETG (Polyethylene Terephthalate Glycol-modified): Durable, impact-resistant, good layer adhesion.

- TPU (Thermoplastic Polyurethane): Flexible, elastic, ideal for soft and flexible parts.

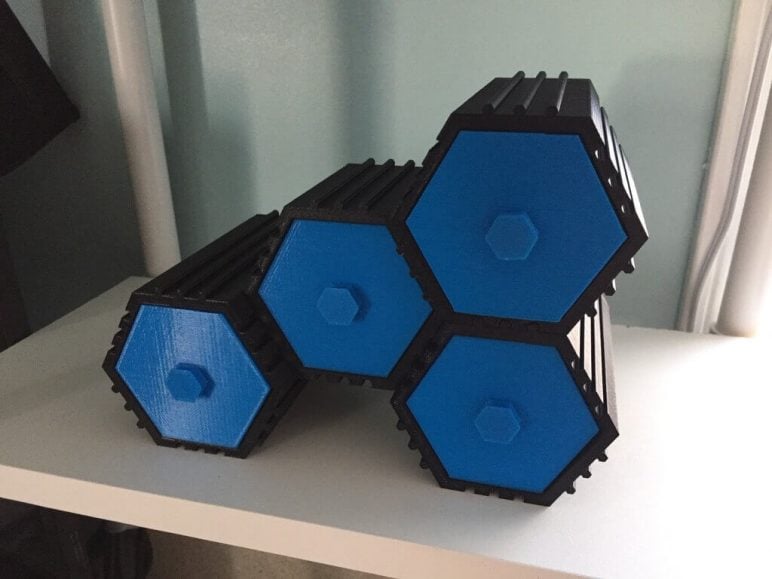

Creating Multi-Material 3D Prints

Multi-material printing involves using different filaments in a single print, allowing for unique combinations of properties and aesthetics. This technique requires printers capable of handling multiple extruders and careful calibration of material settings. The challenges include filament compatibility and potential clogging. Benefits include enhanced functionality and design flexibility.

Examples of Complex 3D-Printed Designs Showcasing Advanced Techniques

Source: all3dp.com

- Technique: Support structures. Example: Intricate overhanging parts in a miniature castle model.

- Technique: Overhangs. Example: A complex, free-standing sculpture with minimal support structures.

- Technique: Multi-material printing. Example: A functional prototype with flexible joints and rigid body components.

Illustrative Examples of Impressive 3D Prints

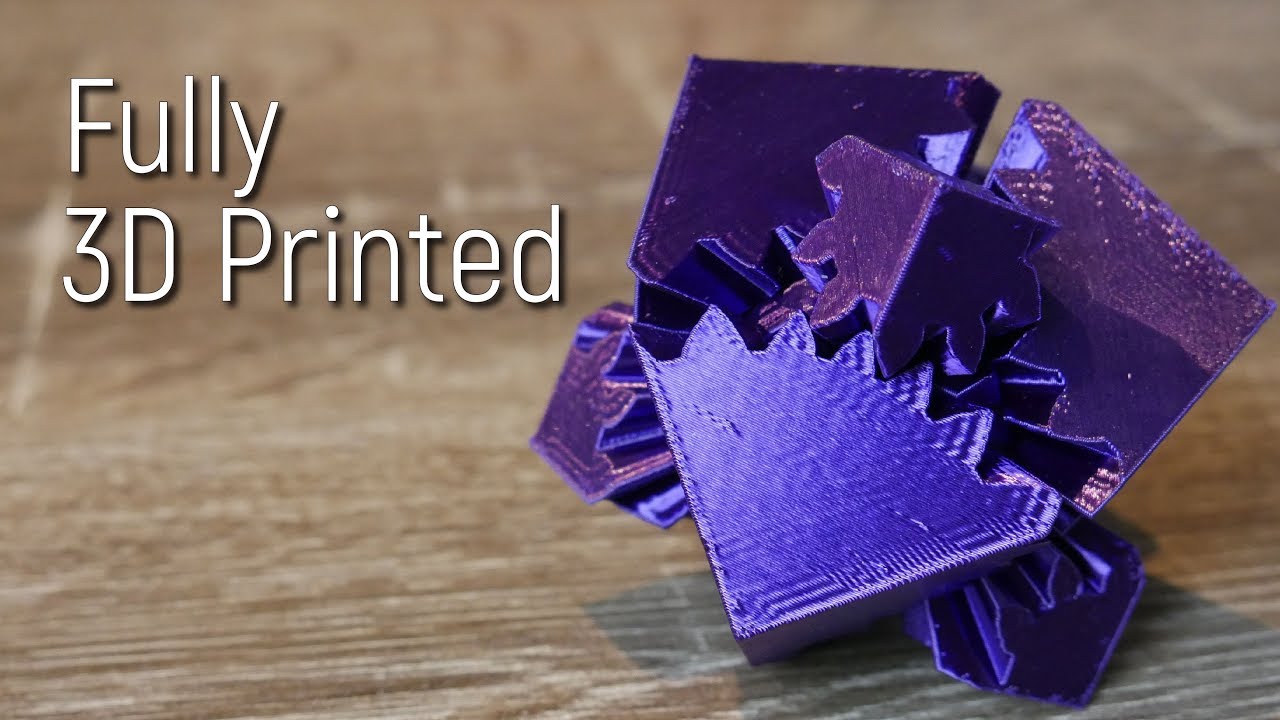

Source: ytimg.com

Let’s explore some examples that showcase the impressive capabilities of 3D printing.

A Large-Scale 3D Printed Project: A Life-Sized Replica of a Famous Sculpture

Imagine a life-sized replica of Michelangelo’s David, printed in sections using a large-format 3D printer. The design process would involve detailed 3D scanning of the original sculpture, followed by meticulous digital modeling to ensure accuracy. Printing would involve careful planning of support structures and assembly techniques. The final result would be a highly detailed and textured replica, capturing the original’s grandeur and artistic nuances.

The texture would be smooth, with fine details like muscle definition and drapery folds clearly visible.

A Highly Detailed Miniature 3D Printed Model: A Clockwork Mechanism

Envision a miniature clockwork mechanism, intricately detailed with tiny gears, springs, and levers, all 3D printed with a high-resolution SLA printer. The design process would involve creating individual components with extremely tight tolerances, requiring precision CAD modeling and careful consideration of material properties. The final product would be a marvel of miniature engineering, with each component precisely fitting and functioning as intended.

The texture would be smooth and highly detailed, revealing the intricacies of the clockwork mechanism.

A 3D Printed Object with a Unique Surface Finish: A Wood-Like Effect

Consider a 3D-printed vase with a realistic wood-like finish. This effect could be achieved using a combination of techniques. First, the vase would be designed with a detailed grain pattern in the CAD software. Then, after printing with a suitable filament (PLA or PETG), the surface could be treated with wood stain or paint to enhance the grain pattern. Finally, a clear coat would be applied to protect the finish.

The final texture would mimic the look and feel of real wood, complete with visible grain lines and subtle variations in color.

Final Wrap-Up

So, there you have it – a glimpse into the awesome world of 3D printing! From functional tools to artistic masterpieces, the possibilities are truly endless. Whether you’re looking to solve everyday problems, express your creativity, or just dive into a fun new hobby, 3D printing offers a unique and rewarding experience. So grab your filament, fire up your printer, and get ready to create something amazing! The only limit is your imagination (and maybe your printer’s build volume).